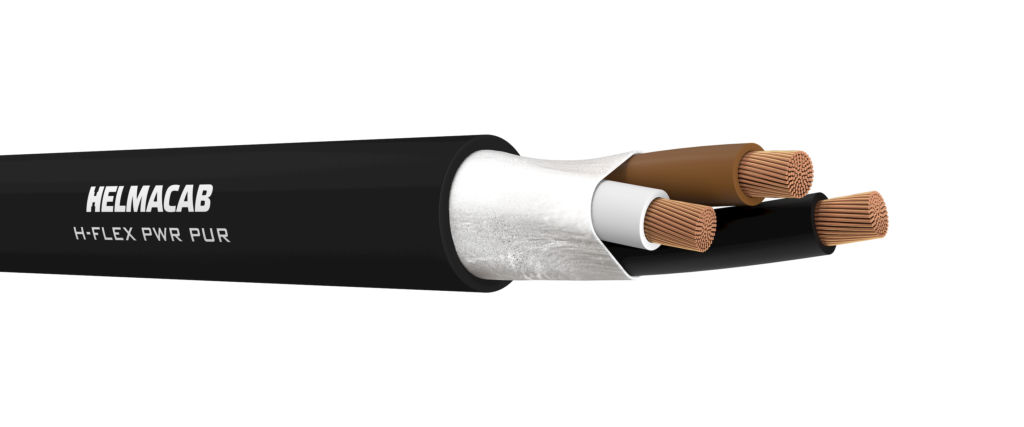

Conductor

Stranded copper conductor 1.0-300 mm², IEC 60228 class 5

Insulation

XLPE plastic

Bedding

Non-woven separator tape

Sheath

Polyurethane compound

Standard colour black, other colours on request

Standard colour black, other colours on request

Application

Intended for flexible, portable and movable applications such as ship-to-shore cable, outdoor cranes and various industrial applications. Suitable for flexible applications in machineries, machine tools, robot technics, and can be submersed into water. Good mechanical characteristics, high tensile strength, resistant to UV, abrasion, chemicals, oil and other fluids. Good winding and unwinding strength. Suitable for drag chain use. Mud resistant according to NEK606.

Core identification

Colour code for 1…4 (5 if PE conductor) core cable, number code for 5…37 core cable

Tensile strength

MAX. TENSILE LOAD WITHOUT STRENGTH MEMBERS: 15 N/mm2 of phases copper cross section

Min. Bending Radius (Installation/fixed)

Fixed: 4 x Ø < 25 mm < 6 x Ø

Mobile: 6 x Ø < 25 mm < 8 x Ø

S-shape deflection: 15 x Ø < 25 mm < 20 x Ø

Mobile: 6 x Ø < 25 mm < 8 x Ø

S-shape deflection: 15 x Ø < 25 mm < 20 x Ø

Marine Type Approvals

ABS, BV, DNV, RINA

Rated voltage

AC 0.6/1 kV (1.2 kV)

DC 0.9/1.5 kV (if voltage to earth does not exceed 0.9 kV)

DC 0.9/1.5 kV (if voltage to earth does not exceed 0.9 kV)

Flame-retardant

IEC 60332-1-2

test for single cable

test for single cable

Halogen-free

IEC 60754 series

Oil resistance

EN 60811-404 – conditions according to EN 50363-10-2

Mechanical flex test

EN 50396 – conditions according to EN 50525

Operating temperature

-60 °C to +80 °C fixed use

-35 °C to +80 °C flexible use

-35 °C to +80 °C flexible use

Max. Conductor temperature

+90 °C