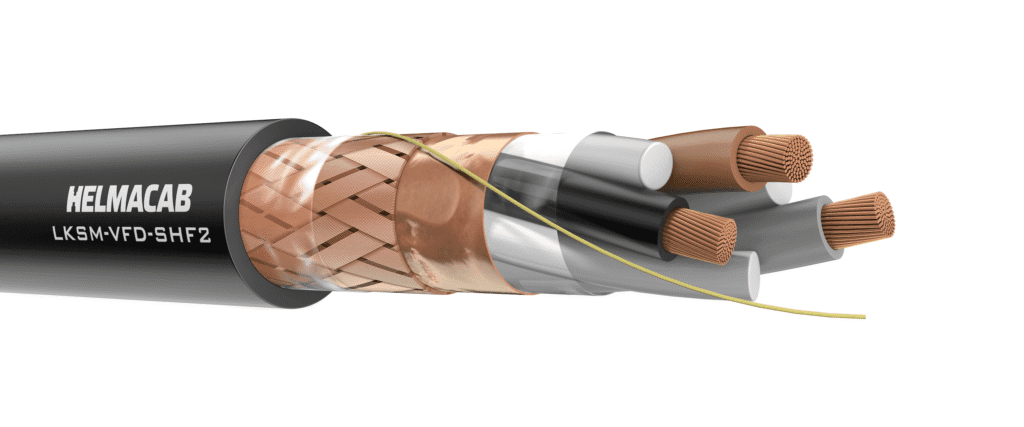

Conductor

Stranded copper conductor 10-300 mm², IEC 60228 Class 5

Insulation

XLPE, IEC 60092-360

Cabling

Cores twisted together. Fillers or dummy cores included in select sizes based on product specifications to obtain symmetrical and round construction, covered by separator tape

Bedding

Lapped tape

Screen

Copper tape, coverage 100%

Armour

Copper wire braid, coverage > 90%, IEC 60092-350

Rip cord

For conductors ≥ 16 mm²

Sheath

Thermosetting polyolefin SHF2, IEC 60092-360

Standard colour black, other colours on request

Standard colour black, other colours on request

Reference standard

IEC 60092-353

DNV-CP-0417

DNV-CP-0417

Application

Specially designed cable for drag chain use. DNV certified according to class program DNV-CP-0417.

Armoured power cable with improved EMC-screening to meet requirements for Variable Frequency Drivers (VFD).

Suitable for voltage peaks up to 3 kV.

Core identification

Colour code

Tensile strength

MAX. TENSILE LOAD WITHOUT STRENGTH MEMBERS:

15 N/mm2 of phases copper cross section

15 N/mm2 of phases copper cross section

Min. Bending Radius (Installation/fixed)

12xØ (In drag chain installation)

Max. Number of bends:

10 000 bends at > 20°C

5 000 bends at > 0°C

Max. Number of bends:

10 000 bends at > 20°C

5 000 bends at > 0°C

Marine Type Approvals

DNV

Rated voltage

AC 1.8/3 kV (3.6 kV)

DC 2.7/4.5 kV (if voltage to earth does not exceed 2.7 kV)

DC 2.7/4.5 kV (if voltage to earth does not exceed 2.7 kV)

Fire performance

IEC 60332-1-2

IEC 60332-3-22

IEC 60332-3-22

Halogen-free

IEC 60754 series

Smoke emission

IEC 61034 series

Oil resistance

IEC 60811-404 conditions according to 60092-360/SHF2

Transfer impedance

IEC 61196-1

(typical value 26 dB over 1 mΩ/m at 100 MHz [20 mΩ/m])

(typical value 26 dB over 1 mΩ/m at 100 MHz [20 mΩ/m])

Min. installation temperature

-15 °C

Operating temperature

0 °C to +80 °C drag chain installation

-40 °C to +80 °C fixed installation

-40 °C to +80 °C fixed installation

Max. Conductor temperature

+90 °C